Humanity’s population is exponentially increasing. Cranes tower over city skylines, racing to build housing and office blocks, each one taller than the last. To do so in a sustainable manner, architects and engineers have recently turned to timber as an alternative to concrete and steel. What do these tall timber projects look like? What are the benefits of timber? How does it cope with environmental challenges, such as the threat of fire and issues relating to water damage? Here, we offer the fresh perspective of an engineering student to give the reader a holistic introduction to the world of tall timber.

Tall timber

noun -Tall buildings (typically over eight stories high) with timber as a key structural element

synonyms - Mass timber, Massivholz

TALL TIMBER

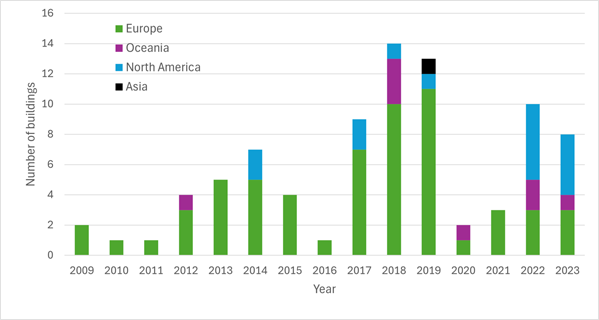

Residents of cities around the globe are more and more likely to work, study, or live in a tall timber building. The Council on Tall Buildings and Urban Habitat carried out a global audit on tall timber buildings in 2022, concluding that 84 buildings over eight stories tall were under construction or completed.1 All buildings contain timber as a key structural element, whether composed purely of timber or a hybrid of timber, steel, and concrete. Construction of tall timber buildings is concentrated in North America, Europe, and Australia, with a pace that has climbed noticeably over the past decade. To explain this trend, we must first ask, “Why would you build a multi-story building out of wood?”

FIGURE 1. Number Of Tall Timber Buildings Constructed Per Year (2009-23). [1] Disregarding The Impact Of The COVID-19 Pandemic On Construction, The Development Pace Has Increased Over The Past Decade. Buildings Are Categorized By Region.

Timber is a renewable resource — it literally grows on trees. Life cycle assessments of tall timber buildings conclude an average 40% reduction in greenhouse gas emissions when compared to conventional multi-story buildings. [2] Timber has high specific strength and stiffness, and being lightweight can be utilized in buildings where the depth of the foundation is constrained, for example due to underground infrastructure such as trains or drains. [3] Timber is also a good structural element for extending building height without overloading existing foundations. [4]

Another key benefit of timber buildings is speed — during construction of an 18-story student residence in Vancouver, Canada, nine workers built two floors a week. [5] The improved program for timber buildings when compared to conventional builds is due to its simpler nature, with quick location and assembly of components. Timber is also very suitable for prefabrication offsite, saving more time. [4] All of these factors combine to reduce construction traffic and noise. [3]

Harder to measure, but no less important, is the social benefit of timber as opposed to steel or concrete. Many technical papers on timber in construction reference well-being in urban contexts. [3,4] It is often discussed anecdotally. Unfortunately, literature on this topic is scarce — a thorough study on the effects of wooden interiors on university student stress levels failed to come to a tangible conclusion. [2]

FIGURE 2. Glulam Arches. [7] Glulam Is Composed Of Many Timber Layers Glued Together With Their Grains Parallel And Can Be Straight Or Curved.

FIGURE 3. CLT. [7] CLT Is Composed Of Three, Five, Seven, Or Nine Layers Of Timber. The Grain Of Each Successive Layer Is Normal To The Previous One.

MATERIAL OVERVIEW: ENGINEERED TIMBER

Wood has excellent strength in compression and bending parallel to the grain. However, its anisotropic properties and naturally occurring defects can lead to unreliable performance. The size of natural timber structural components is also limited. Largescale structural timber components, known as mass timber, were developed relatively recently in Austria in the 1990s, allowing tall buildings to be composed entirely of wood for the first time. Recent inventions optimizing natural wood led to the creation of several new materials such as glulam, cross-laminated timber (CLT) and laminated veneer lumber (LVL).

Glulam (Figure 2) consists of laminated timber layers glued together with their grains parallel to each other. Glulam beams can be straight or curved. Large structural elements such as beams and columns can be made from glulam.

Waste chippings can be repurposed to create LVL. Thin softwood veneers are oriented with their grains parallel to the longitudinal axis of the beam and bonded. LVL sections have a high resistance to axial loads and are therefore used as columns and beams.

CLT contains at a minimum three layers of timber, bonded with grains aligned normal to each other (Figure 3). CLT can contain three, five, seven or up to nine layers of timber. It has a large load-bearing capacity and is often used in walls or floor slabs. [7]

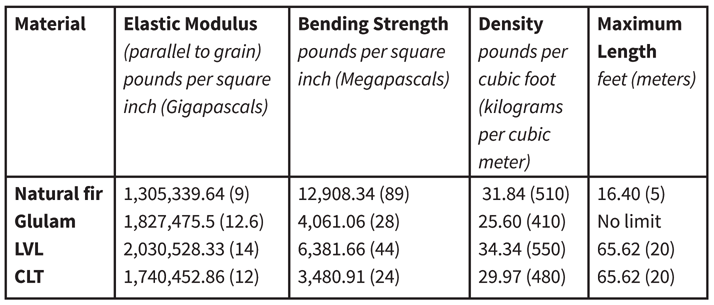

Table 1 compares material properties of natural fir softwood, glulam, LVL, and CLT. All three engineered timbers have a similar modulus of elasticity, in the order of 1,885,490.59 pounds per square inch (13 Gigapascals). The key difference between engineered timber and natural wood is its reliability and size. Natural wooden beams can be up to 6 m long, while CLT and LVL can reach 65.62 feet (20 meters). Glulam theoretically has no length limit as beams can be finger-jointed together continuously. CLT typically has the largest cross section.7,8

TABLE 1. Material Properties Of Engineered Timber At Room Temperature[7,8,9,10]

THREAT OF FIRE

Without a doubt, fire is a legitimate concern when designing a tall timber building. From the Great Fire of London in 1666 to the Grenfell tragedy in 2017, cautionary tales are in abundance.

FIGURE 4. Schematic Of The Cross-Section Of A Charred Timber Beam Including Temperature Distribution [6]

Wood burns. That’s an indisputable fact.

As timber burns, a layer of char is created on its outer surface. Timber charring rates are in the order of 0.02–0.04 inches per minute (0.51–1.02 millimeter per minute). [11] A schematic of a cross-section of a charred timber beam is shown in Figure 4. Char fall-off decreases the load-bearing capacity of a structural component. This phenomenon typically occurs around 572°F (300°C). [12] The European Committee for Standardization recommends the Reduced Cross Section Method to investigate the remaining capacity of a timber component after fire damage. An effective cross section is calculated by subtracting the char layer from the original cross section. [12]

Fire starts with ignition and will continue until burnout or extinguishment. Burnout occurs when all the fuel loads in a compartment have been consumed by fire. Typical steel or concrete buildings include movable fuel loads such as furniture, appliances, and furnishings. Timber buildings include an additional fuel load — their structure. Under extreme temperatures, delamination of engineered timber such as CLT and glulam can occur, where the bond between the material’s constituent layers breaks down. Sections of charred timber as well as protective boards can separate from their parent body, falling from the ceiling and walls.

This adds significant fuel to the fire, with timber having a heat of combustion of 6.80–9.07 megajoules per pound (15–20 megajoules per kilogram). [13]

Alternatively, combustion can be stopped by extinguishment — either from an external source or due to self-extinguishment. Self-extinguishment occurs if there is a lack of oxygen or heat. The difference between fire and flame extinguishment is worth noting. Flames can transition to smoulder, which can pass undetected for days. This significant threat can reduce the load-bearing capacity of structural components, leading to collapse. [14]

Designing for fire safety does not mean ensuring materials are inflammable. Rather, legal standards require that the load-bearing capacity of a building be maintained for a specific period of time, that the spread of flame is limited, and that occupants can be evacuated. Achieving these standards becomes even more difficult at height. It takes longer for all the occupants to be evacuated and it is more difficult for fire fighting teams to reach the source of the fire. Structural failure of the entire building would have catastrophic effects. How then could tall timber projects be considered safe?

A sacrificial layer of timber can be incorporated at the design stage to ensure the structural integrity of a component even after sustaining fire damage. Fire-retardant chemicals or coatings can be applied to timber products to slow fire development at its initial stages. [6] Several studies note the effective use of flame-retardant gypsum plasterboard to encapsulate structural timber elements, thereby preventing charring. [12,13] Sprinklers are also utilized to inhibit fire spread. [13] The construction phase prior to the installation of protective fire measures has been flagged as particularly vulnerable to fire, leading to costly damages and delayed programs. [6]

SUSTAINABLE FOAM PROPORTIONERS FOR VARIABLE VISCOSITIES

FM APPROVED

Experience excellence in environmental safety with sustainable foam proportioners, the ultimate solution for industrial fire protection. Engineered to deliver fluorine-free foam of all viscosities *, our innovative solutions not only enhance safety but also reduce operating costs. Upgrade to greener fire protection technology today.

firedos.com | info@firedos.com | 346-262-6075

*According to the range in FM approval guide

Fire separation is a critical aspect of fire safety design. Structural modeling of a tall timber project must consider how to prevent internal fire spread, for example through ventilation holes or electrical ducts, as well as the performance of the façade in preventing fire from leaping from one story to another. The self-extinguishment properties of charred timber and fall-off times of protective plasterboards must also be taken into consideration. [13]

A review of fire experiments in mass timber compartments detailed 63 studies carried out globally. The authors concluded that lack of data was a significant hurdle in mass timber construction, particularly data relating to fire in large, open-plan compartments. [15] Recent developments include a series of four CodeRed fire experiments carried out inside a compartment with 3,788.9 square feet (352 square meters) of floor space, the largest compartment fire experiment ever carried out. [14] Concerningly, fire safety codes currently lag the pace of construction of tall timber buildings. Fire service personnel are not trained to respond specifically to a tall timber building fire and its unique combustion behavior.

FIGURE 5. A Purpose-Built Compartment On Fire As Part Of A Study Investigating Fire Dynamics In Open-Plan Apartments. [14] It Was Concluded That Fires In Compartments With Exposed Timber Structural Elements Spread Faster And Last Longer Than Fires In Compartments Without Exposed Timber.

WATER ISSUES

Directly in contrast with fire, water is also a limitation of tall timber projects. Timber is porous by nature. A growing tree has a very high moisture content. Once a tree has been felled, moisture slowly evaporates until the timber is in equilibrium with atmospheric moisture. In the industry, this process is called seasoning and can be accelerated by drying timber in a kiln. Seasoning timber can increase its bending strength by up to 60%. [8]

Timber can be exposed to water for several reasons: atmospheric moisture and rain, water from sprinklers or fire fighting hoses, and leaking pipes. Moisture can decrease the durability of timber buildings by reducing strength, accelerating creep, and increasing the likelihood of insect or fungal attack. An increase in moisture content of a structural timber beam can cause it to swell or warp, significantly affecting its load-carrying capacity. Cyclic moisture loading of timber also increases creep deformation. [8]

To promote the longevity of structural timber, the number one guideline is “keep it dry.” The drying rate of timber is far slower than its wetting rate. The construction phase is particularly vulnerable to water damage. It is recommended to cover timber sections during shipping and construction. Exposed timber members should have a protective coating, and upper surfaces should be sloped to ensure water runoff. [5] Fire retardants have been observed leaching out of structural timber elements when exposed to a humid environment. [12]

Extreme flooding events can have a detrimental effect on timber buildings. A study of light timber frame buildings in Malaysia concluded that the cost of repairs after flood damage can reach 50% of the building construction value. [16] In another study, an experimental simulated flooding of timber walls resulted in a 25% reduction in load-carrying capacity. Even after drying, the timber elements were 20% weaker than their original state. [17]

Funnily enough, the presence of moisture reduces the flammability of timber and slows its char rate. Water and fire are opposing threats to timber.

CONCLUSION

Timber as a construction material has been enjoying a revival for the past 20 years, with many hailing it as the building block of the future. Recent advances in material engineering have optimized wood’s natural properties to produce timber components stronger and larger than what nature provides.

The main reason for the recent exponential growth in tall timber projects is the focus on sustainability in material selection and construction. The benefits of building with timber include quicker and quieter construction and increased building height even for shallow foundations.

The construction of these tall timber projects has outpaced the development of international standards relating to fire safety. Studies have investigated the charring behavior of engineered timber and how it affects load-bearing capacity. Further research on fire behavior in timber buildings is required to inform robust safety standards.

Water issues have been proven to reduce the strength and durability of structural timber components. Protecting timber from moisture exposure is imperative throughout the construction and lifetime of a timber building. Extreme flooding is an under-researched threat to tall timber.

The number of tall timber buildings on our skylines continues to increase. International construction standards and fire safety codes relating specifically to tall timber must race to catch up.

AISLING ELLIOTT and GUILLERMO REIN are with Imperial College London.

REFERENCES

[1] D. Safarik, J. Elbrecht, and W. Miranda.. “The State of Tall Timber: A Global Audit,” Council on Tall Buildings and Urban Habitat, 2022, Online: https://www.ctbuh.org/mass-timber-data

[2] D. R. Fell. “Wood in the Human Environment: Restorative Properties of Wood in the Built Indoor Environment,” PhD thesis, University of British Columbia, 2010.

[3] M. Ramage, R. Foster, S. Smith, K. Flanagan, and R. Bakker. “Super Tall Timber: Design Research for the Next Generation of Natural Structure,” The Journal of Architecture, 2017, 22 (1), 104-122, doi: 10.1080/13602365.2016.1276094.

[4] R. Hough. “Rethinking Timber Buildings,” Arup, 2019, Online: https://www.arup.com/perspectives/publications/research/section/rethinking-timber-buildings

[5] J. Y. Wang, R. Stirling, P. I. Morris, A. Taylor J. Lloyd, G. Kirker, S. Lebow, M. Mankowski, H. M. Barnes, and J. J. Morrell. “Durability of Mass Timber Structures: A Review of the Biological Risks,” Wood and Fiber Science. 50 (Special Issue - CLT/Mass Timber), 2018, 110-127, doi: 10.22382/wfs-2018-045.

[6] A. Buchanan and B. Östman. (ed.) “Fire Safe Use of Wood in Buildings,” Global Design Guide, Oxford, CRC Press, 2022.

[7] Structural Timber Association. “Engineered Wood Products and an Introduction to Timber Structural Systems,” Alloa, Scotland, Structural Timber Association, 2014.

[8] K. A. Harries and B. Sharma. “Nonconventional and Vernacular Construction Materials: Characterization, Properties, and Applications,” Oxford, Woodhead Publishing, 2016.

[9] KLH Massivholz GmbH. “Environmental Product Declaration — CLT,” Berlin, Institut Bauen und Umwelt e.V., 2019.

[10] H. Sahin Kol, Y. Sefil, and S. Aysal Keskin. “Effect of Heat Treatment on the Mechanical Properties and Dimensional Stability of Fir Wood,” Research for Furniture Industry, 27th International Conference, 17 September 2015, Turkey, Karabuk University, 2015.

[11] European Committee for Standardization. “Eurocode 5: Design of Timber Structures — Part 1-2: General — Structural Fire Design,” Brussels, European Committee for Standardization, 2004.

[12] B. A. Östman, J. Schmid, M. Klippel, A. Just, N. Werther, and D. Brandon. “Fire Design of CLT in Europe,” Wood and Fiber Science, 50 (Special Issue - CLT/Mass Timber), 2018, 68-82, Online: https://doi.org/10.22382/wfs-2018-041

[13] C. Pettersson. “Fire Safety in Timber Buildings — A Review of Existing Knowledge,” Brandforsk – Swedish Fire Research Foundation, 2020, Online: https://www.brandforsk.se/wp-content/uploads/2020/11/Brandforsk_Report_Fire-Safety-in-Timber-Buildings-1.pdf

[14] P. Kotsovinos, E. Rackauskaite, E. Christensen, et al. “Fire Dynamics Inside a Large and Open-Plan Compartment with Exposed Timber Ceiling and Columns: CodeRed #01,” Fire and Materials. 2023, 47(4): 542-568. doi:10.1002/fam.3049.

[15] H. Mitchell, P. Kotsovinos, F. Richter, D. Thomson, D. Barber, and G. Rein. “Review of Fire Experiments in Mass Timber Compartments: Current Understanding, Limitations, and Research Gaps,” Fire and Materials, 2023, 47(4): 415-432. doi:10.1002/fam.3121.

[16] A. T. Balasbaneh, A. K. Bin Marsono. and A. Gohari. “Sustainable Materials Selection Based on Flood Damage Assessment for a Building Using LCA and LCC,” Journal of Cleaner Production, 2019, 222 844-855. 10.1016/j.jclepro.2019.03.005.

[17] A. C. Bradley, W. S. Chang, andR. Harris. “The Effect of Simulated Flooding on the Structural Performance of Light-Frame Timber Shear Walls – An Experimental Approach,” Engineering Structures, 2016, 106 288-298. 10.1016/j.engstruct.2015.10.010.

Open photo in lightbox

Open photo in lightbox